Description

The simplest air (and smoke) control seals we offer are 188S, 488S, and 388S teardrop (see pages 64-65). These have been tested to BS 476-31.1 and BS EN 1634-3 and have a leakage not exceeding 3m3/m/h i.e. less than 3 cubic metres per metre of frame crack per hour at 25 Pa. Actual figures shown on page 50.

However, Zero has designed and tested other systems against air leakage to demonstrate the effectiveness of these products and materials at higher pressures. They have been tested for air infiltration (positive pressure) where high pressure pushes the door against the seal, and also for the more onerous air exfiltration (negative pressure) where high pressure pushes the door away from the seal. By specifying a complete "Air Control System" you are assured that the components installed for head, jamb and sill will perform properly together.

The table on page 51 shows tests conducted under positive and negative pressure at 76 Pa (25 mph), 100 Pa (28 mph), 150 Pa (35 mph), 306 Pa (50 mph), 688 Pa (75 mph), and 1223 Pa (100 mph).

Positive pressure (air infiltration) - where high pressure pushes the door against the seals. For example, external outward opening doors with panic exit devices.

Negative pressure (air exfiltration) - where high pressure pushes the door away from the seals. For example, computer rooms, halon systems, hotel bedroom doors etc. Negative pressure tests are the more onerous.

The higher the air pressure differential, the better the quality of the gasketing is needed. Adjustable gasketing facilitates installation and allows adjustment when needed for

consistent performance over time.

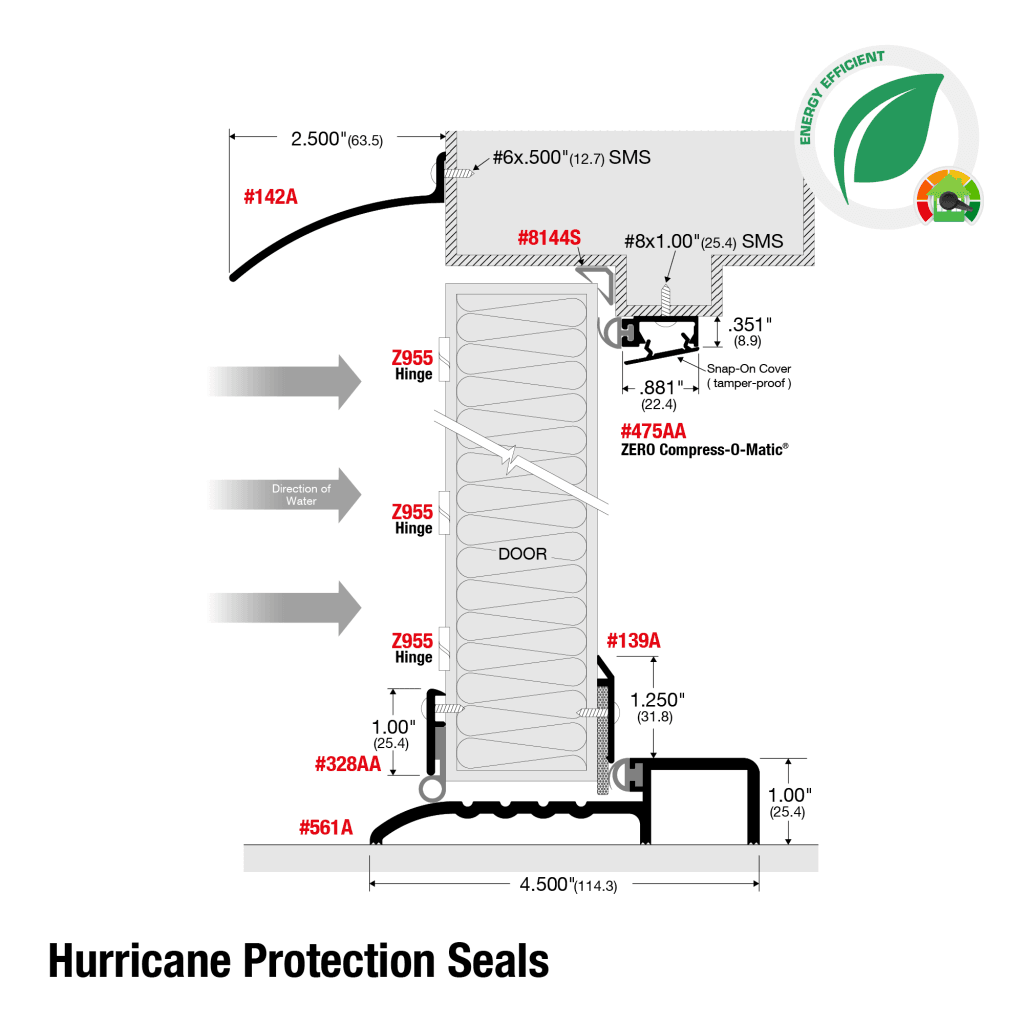

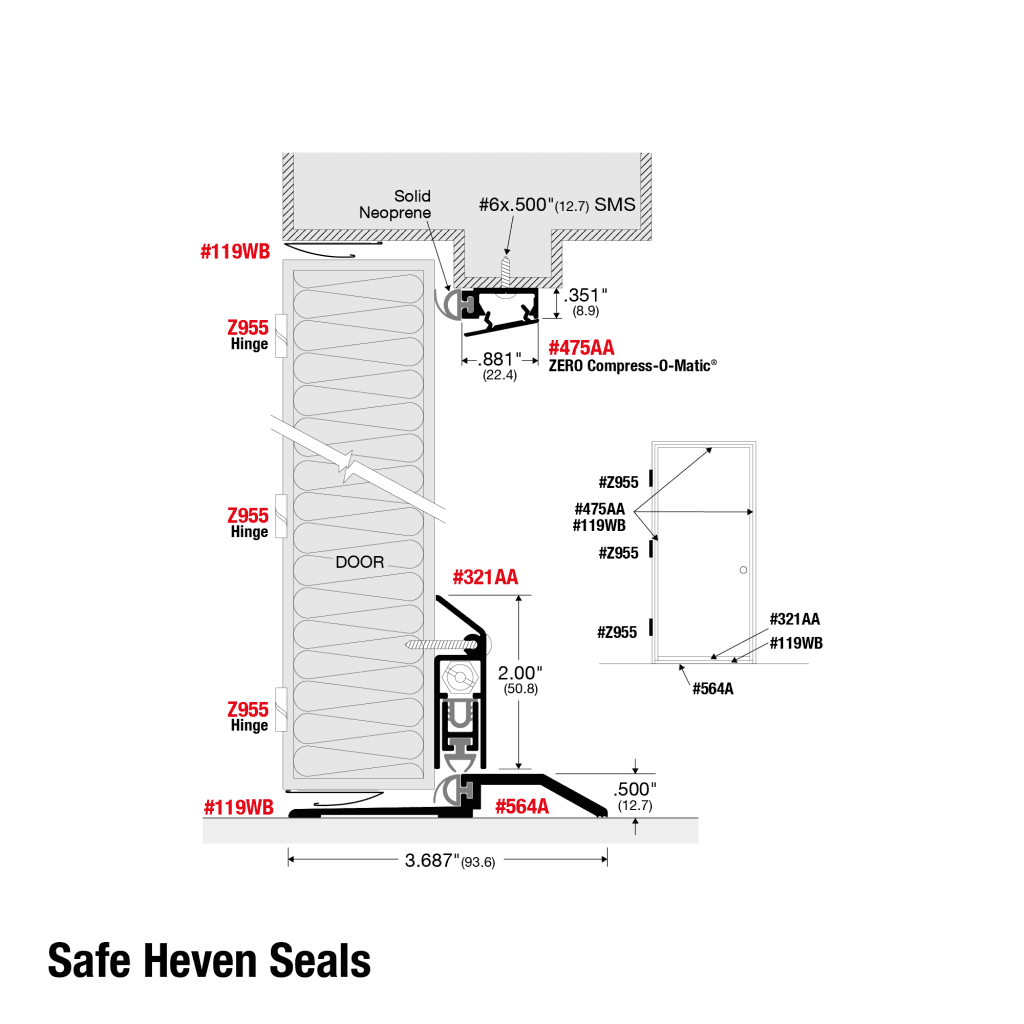

Below we show two specific sets of seals that have been tested; the Dade County set and the Safe Haven set.

However, Zero has designed and tested other systems against air leakage to demonstrate the effectiveness of these products and materials at higher pressures. They have been tested for air infiltration (positive pressure) where high pressure pushes the door against the seal, and also for the more onerous air exfiltration (negative pressure) where high pressure pushes the door away from the seal. By specifying a complete "Air Control System" you are assured that the components installed for head, jamb and sill will perform properly together.

The table on page 51 shows tests conducted under positive and negative pressure at 76 Pa (25 mph), 100 Pa (28 mph), 150 Pa (35 mph), 306 Pa (50 mph), 688 Pa (75 mph), and 1223 Pa (100 mph).

Positive pressure (air infiltration) - where high pressure pushes the door against the seals. For example, external outward opening doors with panic exit devices.

Negative pressure (air exfiltration) - where high pressure pushes the door away from the seals. For example, computer rooms, halon systems, hotel bedroom doors etc. Negative pressure tests are the more onerous.

The higher the air pressure differential, the better the quality of the gasketing is needed. Adjustable gasketing facilitates installation and allows adjustment when needed for

consistent performance over time.

Below we show two specific sets of seals that have been tested; the Dade County set and the Safe Haven set.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.