Description

With such a vast array of thresholds in the Zero range, we have often been asked over the years which is the best non-slip threshold we offer. In 2017 we undertook some independent laboratory anti-slip testing to BS 7976-2:2002 Pendulum Testers Method of Operation which measures the dynamic coefficient of friction using pendulum floor testing. A total of eight thresholds were tested in both dry and wet conditions with two different sliders representing pedestrians barefooted and shod with footwear, in accordance with UKSRG (UK Slip Resistance Group) and HSE guidelines. These thresholds were 6710A, 6710A-E, 548A, 548A-E, 3676A, 3676A-E, 6575A and 232A/236A; these are representative of our wide range of Modular Thresholds, 6.4mm Low Flat Thresholds and Traction Tread™ Thresholds which have various infills to aid grip. Every Zero threshold tested received a 'low risk' (lowest possible) classification (36+ PTV) in dry conditions, with the majority of those thresholds tested also receiving this classification in wet conditions.

Whilst there is no express requirement to achieve a 36 Pendulum Test Value (PTV) or greater to BS 7976-2 in the conditions of end use, it is a clear requirement of UK Law that floor surfaces must not present risks to health. In many legal cases a 'low risk' classification (36+ PTV) has been a key point of interest in determining whether a surface is safe or slippery. Test evidence in regards to the slip rating of thresholds is regularly asked for in public transport applications. The Workplace (Health, Safety and Welfare) Regulations 1992 state that floors shall be suitable for their purpose, and shall not be slippery so as to expose a person to a risk to their health and safety.

TEST RESULTS

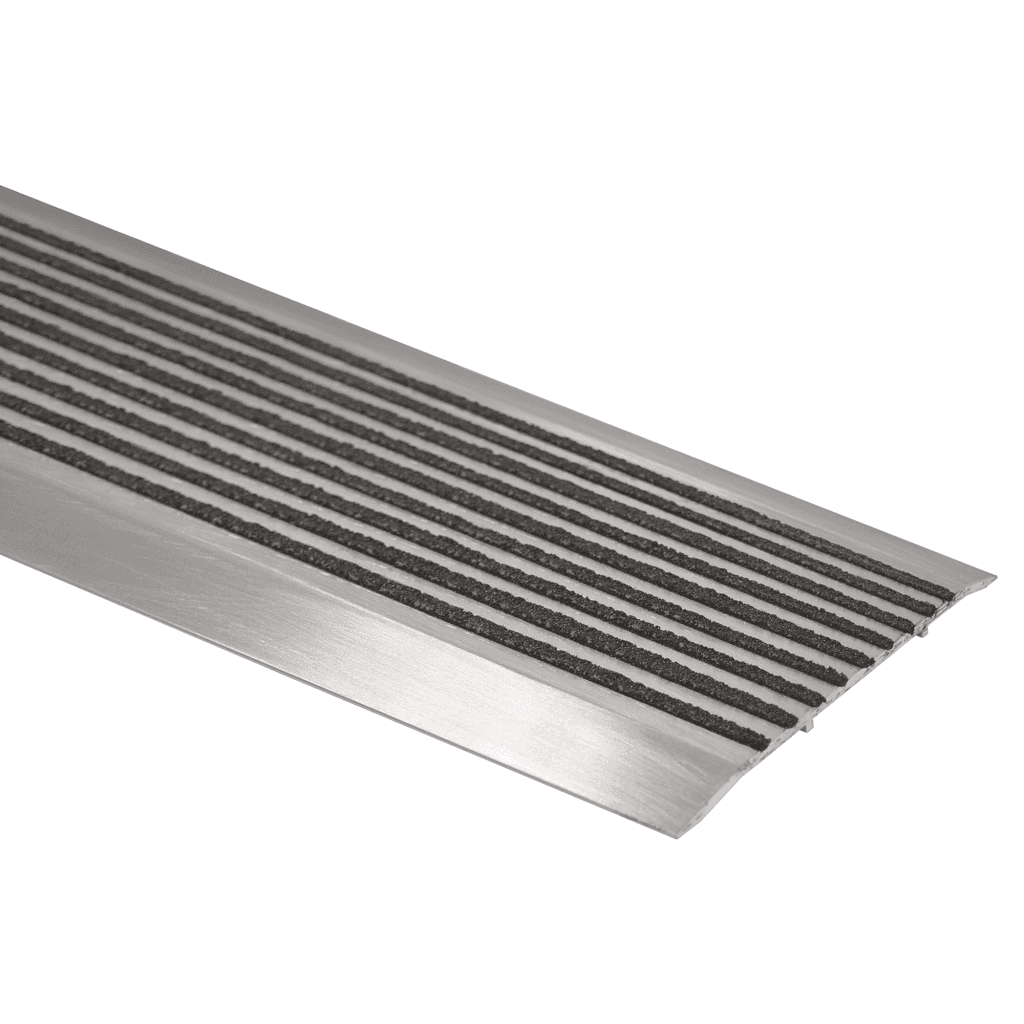

Whilst there is no worldwide recognised 'definitive slip risk test', BS 7976 (The Pendulum) is the most widely recognised in the UK and it is the HSE's preferred method of slipperiness assessment. Our tests showed that Zero thresholds 548A-E, 6710A-E and 3676A-E all with non-slip epoxy abrasive particles bonded into the grooves performed best, particularly in wet situations. The results for these three thresholds are shown in the table above, and the Test Report confirms that the test results on each of the three profiles should be considered an accurate representation of the performance of that particular profile, such that they should apply to all identical profiles regardless of product length, width, name or reference. Had specimens of the same profile been supplied in larger/varying sizes, tests would still have been conducted on the same contact patch, producing the same results. A copy of Test Report Ref 1931ZERO040517 dated 04.05.2017 is available on request. On this basis, we recommend the range of thresholds on this page for public areas where there are risks of personal injury from slipping. The suffix -E after the product code denotes epoxy abrasive particles bonded into the grooves which is an extremely durable surface and provides a high degree of safety against accidental slips.

SIZES & AVAILABILITY

It is best to order this product to suit site sizes as it is difficult to cut or "work" on site because of the hardness of the abrasive epoxy, so all thresholds on this page will be manufactured to special order. These thresholds are all supplied undrilled (NH no holes) to offer more options for site installation. Maximum length 3048mm. Thresholds are mill aluminium silver finish and abrasive epoxy inserts are black. If luminescent abrasive epoxy is required, please suffix the reference -EL.

Whilst there is no express requirement to achieve a 36 Pendulum Test Value (PTV) or greater to BS 7976-2 in the conditions of end use, it is a clear requirement of UK Law that floor surfaces must not present risks to health. In many legal cases a 'low risk' classification (36+ PTV) has been a key point of interest in determining whether a surface is safe or slippery. Test evidence in regards to the slip rating of thresholds is regularly asked for in public transport applications. The Workplace (Health, Safety and Welfare) Regulations 1992 state that floors shall be suitable for their purpose, and shall not be slippery so as to expose a person to a risk to their health and safety.

TEST RESULTS

Whilst there is no worldwide recognised 'definitive slip risk test', BS 7976 (The Pendulum) is the most widely recognised in the UK and it is the HSE's preferred method of slipperiness assessment. Our tests showed that Zero thresholds 548A-E, 6710A-E and 3676A-E all with non-slip epoxy abrasive particles bonded into the grooves performed best, particularly in wet situations. The results for these three thresholds are shown in the table above, and the Test Report confirms that the test results on each of the three profiles should be considered an accurate representation of the performance of that particular profile, such that they should apply to all identical profiles regardless of product length, width, name or reference. Had specimens of the same profile been supplied in larger/varying sizes, tests would still have been conducted on the same contact patch, producing the same results. A copy of Test Report Ref 1931ZERO040517 dated 04.05.2017 is available on request. On this basis, we recommend the range of thresholds on this page for public areas where there are risks of personal injury from slipping. The suffix -E after the product code denotes epoxy abrasive particles bonded into the grooves which is an extremely durable surface and provides a high degree of safety against accidental slips.

SIZES & AVAILABILITY

It is best to order this product to suit site sizes as it is difficult to cut or "work" on site because of the hardness of the abrasive epoxy, so all thresholds on this page will be manufactured to special order. These thresholds are all supplied undrilled (NH no holes) to offer more options for site installation. Maximum length 3048mm. Thresholds are mill aluminium silver finish and abrasive epoxy inserts are black. If luminescent abrasive epoxy is required, please suffix the reference -EL.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.